Throughout the winter quarter, all of our subteams made significant progress towards the SUAS competition in June, which now puts us in a good position to begin rapidly testing and iterating on all of our systems during the coming quarter. We are planning a large quantity of test flights throughout the first half of the spring quarter mainly focused on capturing all of the footage and recording all of the data needed for our Flight Readiness Review video, which is due on May 1st. Beyond that, we will continue to refine our system and increase our confidence in its correctness until we depart for Maryland in June. The road to get here, however, was full of a lot of hard work, and all of our subteams would like to share what they have achieved throughout the last eleven weeks.

Airframe

The winter quarter at TUAS has had us all in full swing manufacturing mode! From week one through week ten, all eleven of our technical teams have taken their preliminary designs established at the end of fall quarter and turned them into complete subsystems that will be implemented into the competition aircraft. From prototype to completed component, each team has managed to optimize the design for manufacturability under cost constraints, deliverable deadlines, and quality standards, and have successfully worked alongside several other teams to integrate their components into the complete aircraft.

However, it would be completely inaccurate to say that the manufacturing process this year has been smooth. Rather, it was very educational for how we are able to produce reliable and repeatable quality components given new manufacturing procedures (sounds like a problem we might take on in industry doesn’t it?!). From forged carbon molded parts to 3D printed molds utilized for composite layups, we have identified, and successfully achieved new methods of manufacturing at a reduced cost that can produce parts of near equivalent quality compared to methods requiring much higher investments and better tooling. Additionally, with a new aircraft design this year being based on a Vertical Take Off & Landing (VTOL) design, we have taken on a whole new suite of design criteria that will need to be considered to successfully achieve stable flight.

With new objectives and challenges this past quarter, we have been able to grow our team by over 100% from past years which has been a tremendous help in tackling each diverse component on our aircraft. It has been especially impressive observing how new members on our team – who make up the majority of the team – have grown from nearly no flight intuition, to executing complex design work, planning for manufacturing, and prototype iteration to best suit their component within the overall aircraft.

Moving forward, as we enter the spring quarter, we will be finalizing the assembly of our aircraft along with all embedded integrations in order to get on the flight line as soon as possible to begin test flights. With technical review deadlines and the competition around the corner, we are seeking to gain as many flight hours as possible and work out any last minute manufacturing adjustments to best optimize our aircraft’s flight performance.

Embedded

The embedded team’s focus has been wrapping up our projects as quickly as possible to ensure ample time for testing before competition. The power board is well underway to simplify the safe distribution of power for all our components, we have made breakthroughs with Bluetooth and WiFi communication for the guided payload, and have successfully implemented the antenna tracker’s UDP connection, enabling it to function wirelessly.

The signals board is nearing completion and the goal is to finish the final board design that will be used on the plane by week 2 of the quarter. The new HSTS016L current sensor brought unexpected challenges that took longer to resolve than we hoped, but once we overcame those it was clear that it was the best solution for non-invasive, high-current measurements. For The Marius we use a 100A version to measure current drawn by the ESC, but since the VTOL has the potential to pull more power we also bought a 200A model to future-proof the design. Once the signals board is complete, we will join the guided payload team to help them with the mission-critical task of making sure our water bottles land on their targets.

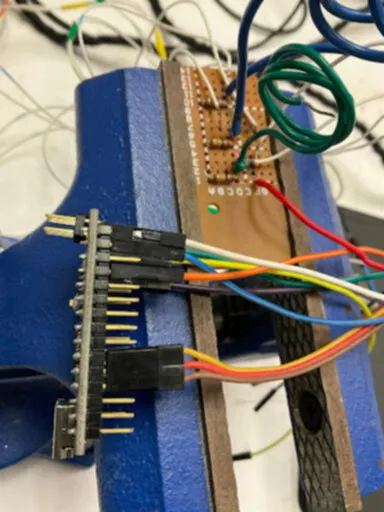

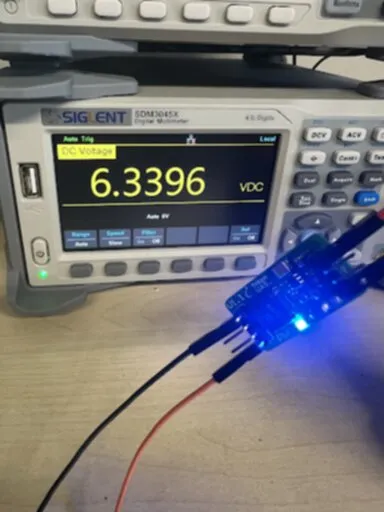

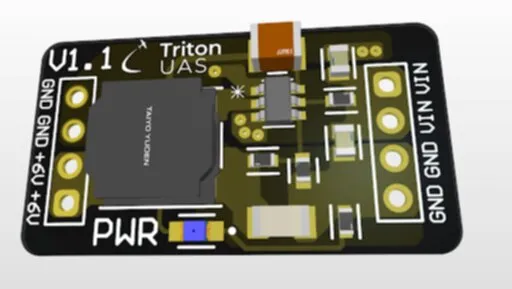

We have also made significant progress towards the completion of our power distribution board over the course of the Winter quarter, even ordering and testing a small module design that will be integrated into the larger PCB when finished! The module, a 14.8V->6V buck converter, will power our servo rail, enabling the plane to control its ailerons and elevators at will from the convenient power of a single 4S LiPo battery. In addition to this module, designs for the other buck converters necessarily powering the RFD, pixhawk, signals board, and airdrop servos is well underway. This leaves just the PoE injector boost converter remaining to integrate into the design, and afterwards the whole board will be ready to ship, assemble, and test.

Top Right: Close-up of buck converter module’s components.

Bottom Right: Buck converter module 3D schematic in Altium Designer.

The spring quarter we will finalize the battery design we’ll use. The battery bulkhead design has been for mounting the 18650 Lithium-ion cell batteries, but due to member attrition we have unfortunately not made progress on this project. Pursuing the 18650 cell design gives us the potential to eliminate the “power squid” (big ugly cable to the ESC) we have with our current 4s LiPo batteries in a 3s2p configuration, and get more flight time for the same volume due to the higher energy density of 18650 cells. This will be more important than ever with the more power-hungry VTOL design.

Since we have been focusing mainly on the more flight-critical projects such as the antenna tracker and power board, we will be looking to pick up the work on our airdrop mechanism and guided payload system this next quarter. This work will need to be accelerated greatly in order to prepare it for the approaching FRR deadlines, but we are confident that this is an achievable goal. As we have made progress on other projects in the Winter quarter, we have been growing our skills in PCB design and microcontroller programming, which will be highly applicable to overcoming the engineering challenges awaiting us in the airdrop task. For the embedded team, the upcoming Spring quarter is going to require a lot of hard and efficient work, and will be an exciting and rewarding experience for leads and members alike.

Software

The software team has made steady progress throughout winter quarter on all of our projects, laying down the foundation so that we can begin rapidly testing our systems at test flights. Namely, we have put in significant effort into our ground control station’s frontend interface and our onboard computer’s path planning algorithm, localization algorithm, machine learning pipeline, and general infrastructure.

With the help of several software members, we have nearly finished the development of our frontend website which allows us to monitor the progress of the mission through a web-view. It now can handle manual bottle matching to audit and potentially override our autonomous target detection, and it also lets us completely specify a mission, upload it to the plane, and then validate that it is correct. Only minor improvements to the frontend are now needed, which includes connection status monitoring, so that we have all of the information needed to monitor our autonomous flight. For next quarter, work on the ground control station will primarily focus on finishing those remaining frontend features, and implementing the necessary backend functionality to connect to our other main project: the onboard computer.

One of the main functionalities of the onboard computer is to plan out the path of the plane, and throughout the last ten weeks our path planning algorithm has progressed from being just an idea to being completely implemented—with some minor adjustments to be made over time. To summarize, we re-implemented our Python RRT* path-planning algorithm in C++ to make it much faster so that we can potentially use it for real time path planning in the future. In addition, we also developed plotting code so that we are able to generate images and animated GIFs of the algorithm itself. In addition, adjacent to path planning, we have also made significant progress on our Mavlink client, which allows us to communicate with the flight computer and send these planned paths to the plane itself. Future progress on path planning for this year will mainly focus on applying the algorithm to cover the search zone where we need to use our camera to identify all of the ground targets.

The localization algorithm, the component of the onboard computer that identifies the location of ground targets, also saw significant progress throughout the quarter. Thanks to our work on improving our localization testing suite last quarter, we were able to iron out several bugs in our existing implementation. Now, the algorithm is consistently less than 10 feet off the expected position. This is a huge improvement compared to the hundreds or thousands of feet that our previous implementation was off by. We are also working to gain precision wherever possible. Additionally, we are trying alternative algorithms and seeing how we can leverage them together to have the most accurate results.

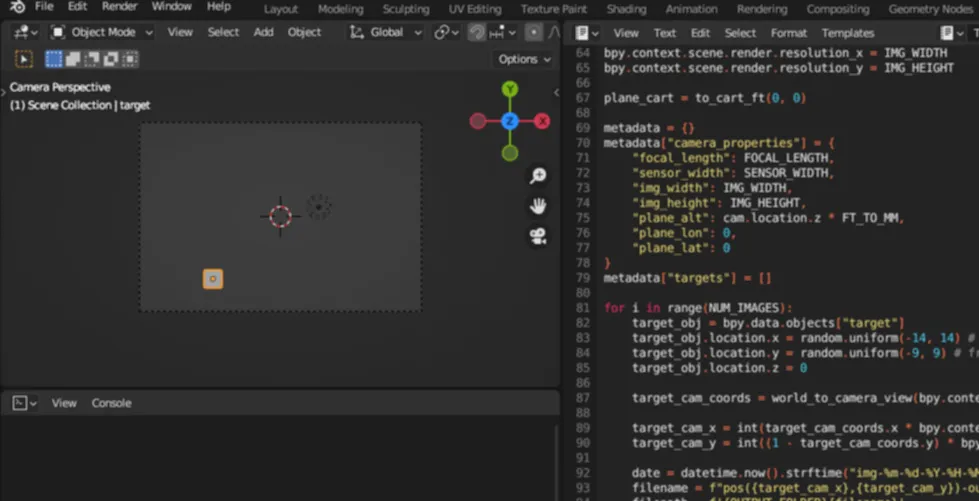

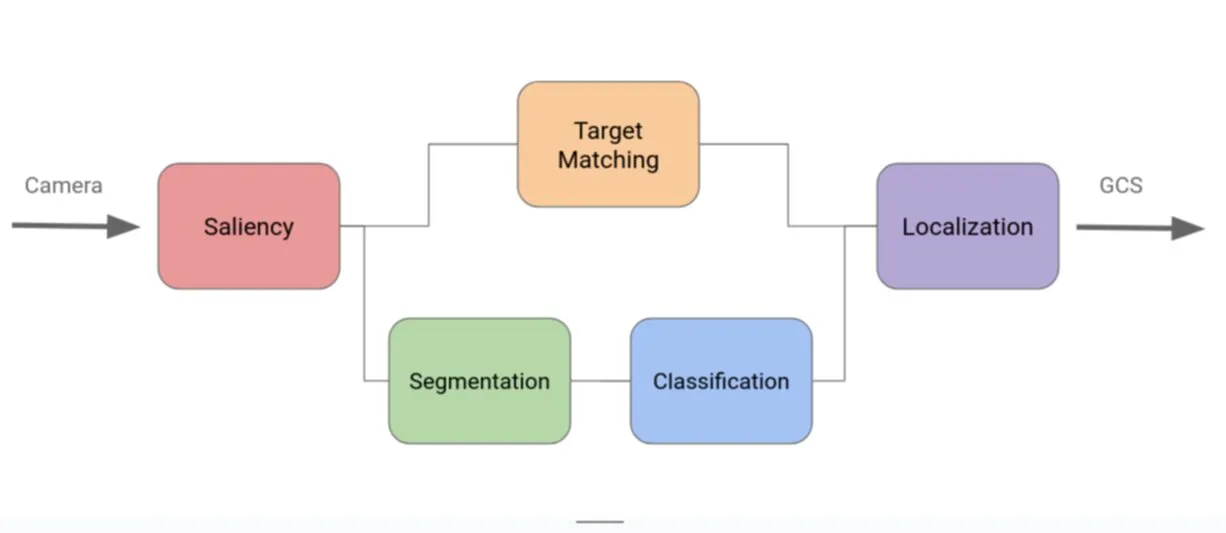

The team has also been working towards integrating our computer vision pipeline into the new on-board computer. The computer vision pipeline is essential to our ability to autonomously carry out competition objectives. It allows our system to automatically identify ground targets to accurately drop the correct water bottles. The pipeline is broken up into several stages that each contribute towards correctly identifying the objects. For example, the saliency stage is responsible for detecting any potential targets from our aerial photos, then passing the result to the next module in the pipeline. Many of these modules are neural networks that are implemented with Pytorch. To use these models during flight, they must be integrated into the rest of our on-board computer. Throughout the quarter, there’s been a large effort among several software members to integrate all the stages of our computer vision pipeline. In the process, members have learned how to interface with Pytorch’s C++ API (Libtorch) and become familiar with integrating machine learning models into a larger system. At this point, we’ve finished integrating all but one of our modules and are almost ready to test it with the rest of the system.

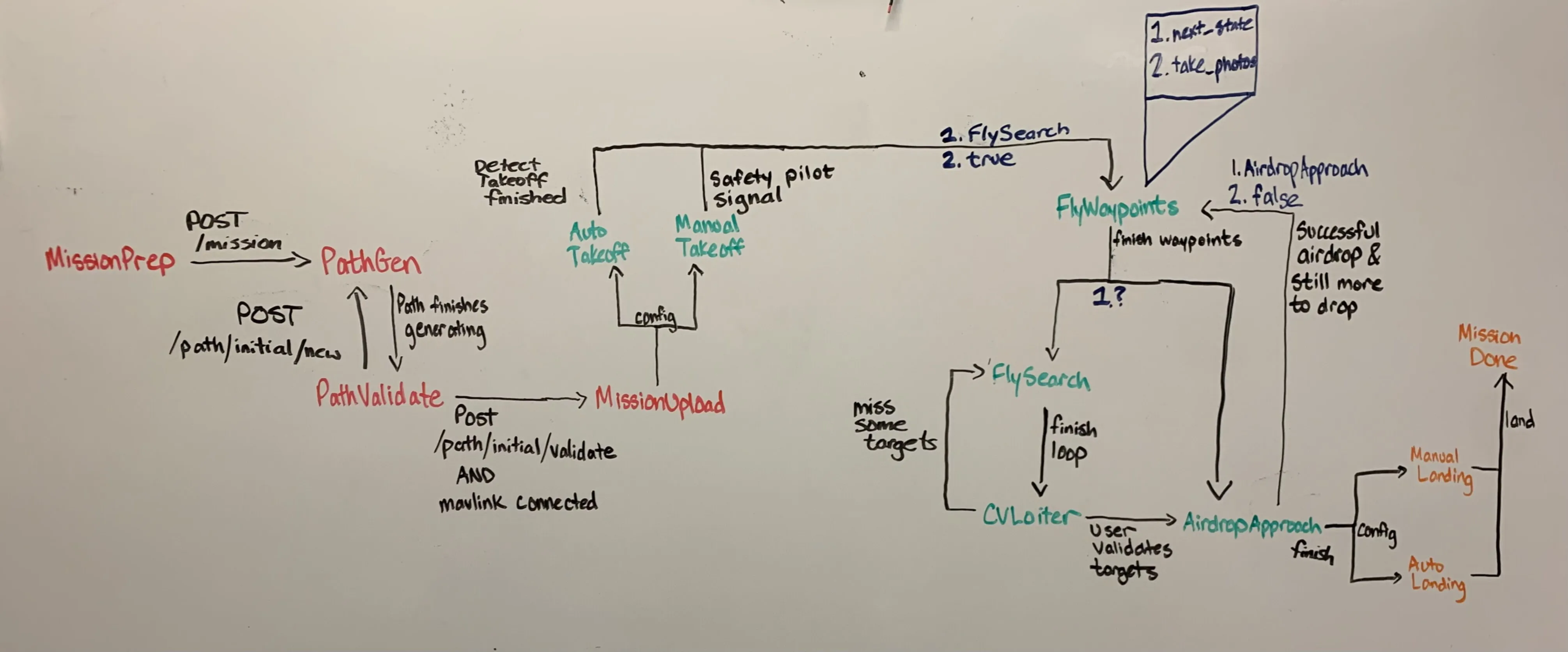

We have also slowly been building out the behind-the-scenes infrastructure of the onboard computer so that all of the individual modules can communicate with each other and be run at the correct time. The core idea we have applied is viewing the onboard computer as a state machine, wherein we divide the mission into a series of “Ticks” (or States), and for each tick define (1) what the plane should be doing during that tick and (2) how it should transfer control into a different tick. This model allows us to develop different parts of the system in parallel, since we have already planned out the behavior of all of the ticks and decided on how they interact with each other. So far, we have implemented all of the ticks for everything relating to setting up the mission, and next quarter we will focus on connecting the aforementioned modules (path planning, Mavlink, computer vision pipeline) with the Tick architecture of the system in order to implement the logic necessary for the actual mission itself.

Overall, the software team has a lot to be proud of this quarter and has made great strides towards getting the critical components of our system ready for competition.

Business

The Business Team began the Winter Quarter with a game night in the Seventh College Game Room, offering an assortment of board games, table tennis, and foosball, alongside food and drinks, to foster engagement and provide an opportunity for people from separate sub-teams to get to know each other.

This was followed by a beach social at La Jolla Shores, where the team participated in various beach games and a jump into the ocean. After everyone had finished playing games and drying off, we witnessed a beautiful sunset over the ocean!

During the San Diego Festival of Science and Engineering, the team showcased our engineering projects, notably our onboarding aircraft, The Marius. This demonstration highlighted our technical expertise to a diverse audience, ranging from young students to industry professionals, and played a crucial role in promoting STEM interests. Hundreds of event participants visited our booth!

Concurrently, the team continued its fundraising activities, collaborating with local businesses like Tapioca Express and Somi Somi, to support our financial goals.

Efforts to secure corporate partnerships advanced through meetings with key figures from the Jacobs School of Engineering IDEA center, aiming to obtain corporate affiliate partner sponsorships. This endeavor is pivotal in fostering industry connections and securing sponsorships aligned with our club’s objectives.

In preparation for the SUAS competition, the team initiated the creation of the Flight Readiness Review Video (FRR) in March. This video, a comprehensive overview of our system and team, is crucial for our participation in the upcoming competition.

Through these activities, The Business Team has played a key role in enhancing our club’s community presence, securing financial stability, and preparing for future competitions.

Moving Forward

Winter quarter was filled with rapid development of all of the aircraft’s parts and functions. Moving into Spring quarter, our focus will shift to testing the aircraft’s performance capabilities in flight to prepare for the competition in June. This includes flying while in manual and autonomous mode, testing airdrop and camera gimbal integration, and training our computer vision model with the camera in flight. We are also putting more focus into creating and completing the FRR video in order to be fully eligible for the competition. We are excited for what’s in store for us and all subteams will continue to work hard to be ready for the competition.