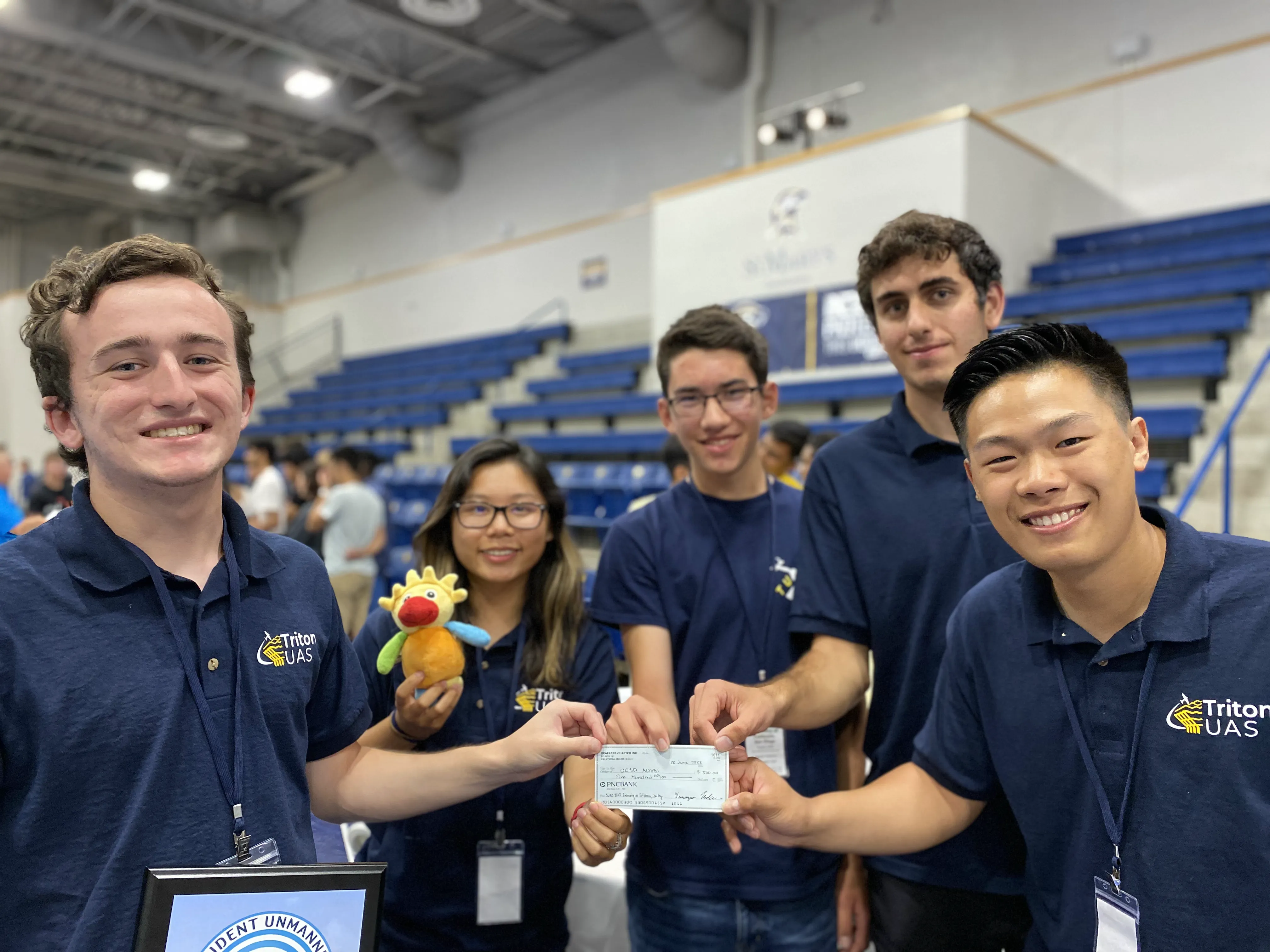

After two years of competition cancellations due to the COVID-19 Pandemic, Triton UAS attended the 2022 AUVSI Student Unmanned Aerial Systems Competition, hosted by the Seafarer Chapter of the AUVSI. We are proud to announce that we placed 5th out of 71 teams! Additionally, we placed 4th in flight mission score. On top of this, we had the highest ranking fixed wing plane and represented the highest ranked American university at the competition. In addition, we placed 16th for Technical Design Paper which was submitted as a detailed report of our overall system design and 22nd for Flight Readiness Review which is a video outlining our testing results and our level of preparedness for competition.

On the community involvement side, Triton UAS held an outreach event with Del Norte High School’s Computer Science class. Our presentation gave an overview of airframe, embedded, and software subteams’ projects with the purpose of sparking interest in engineering as well as highlighting the importance of applying classroom knowledge to real-life problems.

While preparing for competition, Triton UAS improved systems across the airframe, embedded, and software subteams. With each development, team members gained practical, hands-on experience and the team learned many lessons. The airframe team designed, built, and tuned a new competition airframe. In addition, the aircraft design optimization program was improved and performed more in depth analysis on potential new plane designs. As a collaboration between the airframe and embedded teams, a new unmanned ground vehicle (UGV) design was made. Additionally, the embedded team iterated on the power board and signals board designs while also working towards the antenna tracker. The software team made considerable progress, including overhauling the ground control station, greatly improving the accuracy of several computer vision models, and implementing a new path planning algorithm.

Airframe Team

Designing and Manufacturing Duckasaurus

With the unfortunate crash of our main flight platform, Swallow, two months before competition, the airframe team had to design and manufacture a new airframe. One option was to use a commercially bought airframe, Ranger. However, the Ranger limited our scope to attempt computer vision and UGV. Our second option was to purchase another commercially available airframe, such as the Swallow. However, the Swallow and many other commercially available airframes are not suitable for the competition due to its heavy payload requirements. As a result, many of these airframes are difficult to maneuver leading to more crashes, delays to the system development, and lower expected score at competition. With these shortcomings, we decided to design and manufacture our own aircraft, Duckasaurus. Duckasaurus was designed to be inexpensive, easy to manufacture, maneuverable, and large enough to carry all necessary electronics and payload. The theory behind the design stemmed out of a system-wide goal towards simplifying designs. By simplifying the design, the ease of manufacturing is greatly improved, allowing for more reliable, repeatable, and rapid development of the system. In the end, Duckasaurus was manufactured quickly, able to carry the payload, and maneuvered with ease towards its top 5 finish.

Design Optimization Program

Throughout the course of the year, we overhauled the gradient-based aircraft design optimization codes in our MATLAB code. We began the process of transferring over models from the MATLAB code to ADOPT, the Python code, to be applied to our new plane, Carbon Copy. Additional models including an analytic weight model, a mass properties model, and an aerodynamic loads model.

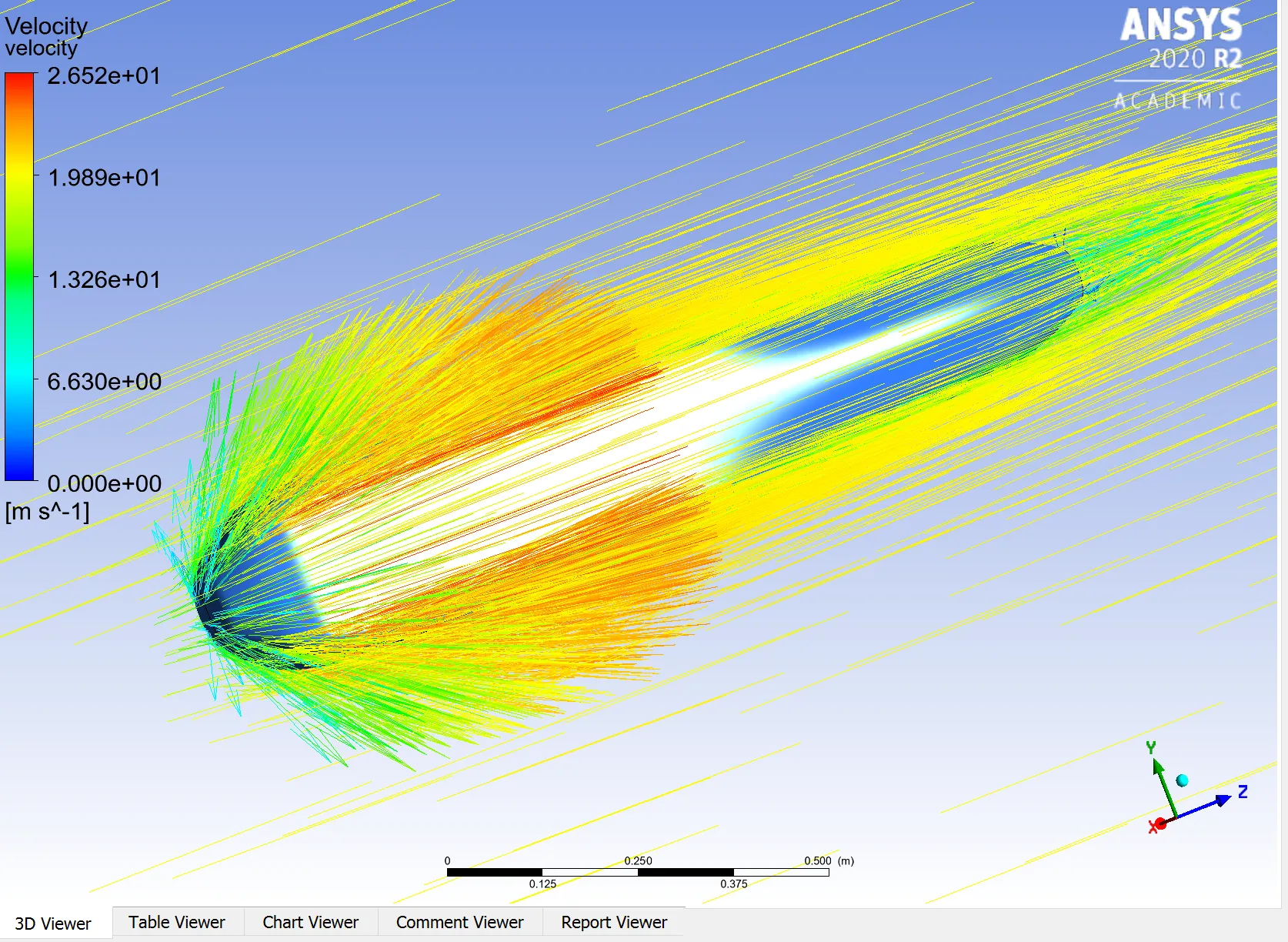

Analysis

On the analysis side, members created and ran ANSYS Fluent models using the most up to date benchmark designs. A larger focus this year was on meshing techniques in order to properly model the boundary layer.

Unmanned Ground Vehicle

For the UGV, we redesigned the chassis to ease the tolerancing process and reduce the amount of support material needed in comparison to the previous model. This redesign stemmed out of our system-wide goal towards simplifying designs. In this case, we can reduce the amount of time spent developing CAD models in Solidworks and 3D printing the chassis, while also adding more flexibility in the payload layout.

Embedded Team

Signals Board

In the past year, we have worked on expanding the capabilities of the signals board to collect and relay telemetry information about the plane. The previously pursued functionality has been maintained, namely the measuring and relaying of the temperature of key components to ensure their safe in-flight operation. In addition to this, we have designed and fabricated a voltage divider circuit to allow the Arduino to read and record several high-voltage readings at once without sustaining damage. We have also selected and purchased an ammeter system to measure the capacity of the battery as it is used up. All of the design decisions have been thoroughly documented in a way that will be applicable to future iterations of the signals board, while also providing the specific parameters for the parts in use currently. We have also studied and written communication software in MavLink to integrate the sensor data with our plane’s other controllers. By the end of the next quarter, we expect to successfully run full-system benchtop integration tests and collect data from several sources simultaneously.

Antenna Tracker

The antenna tracker’s software was completely rewritten to better accommodate for the new ground control station changes. We decided to write everything in Python due to its ease of use for high-level design and number of relevant libraries that could be used to implement the tracking algorithm. For testing, we started out by using SITL to simulate the plane flying in Mission Planner and QGroundControl. After successfully getting the antenna tracker to point at the simulated plane’s location in real time, we tested the antenna tracker outdoors with a real plane. By the end of the year, the antenna tracker was able to point at the plane’s physical location in real time with a small amount of error.

Unmanned Ground Vehicle

The embedded UGV team worked on setting up the electronics for the UGV and making a controller for driving. We identified the Raspberry Pi Zero as the vehicle computer due to its small form factor and satisfactory processing capability. We developed a mock test bench for the Raspberry Pi connected to a DC motor controller and GPS. The first program we tested was successful in simple motor control. Next, we developed GPS programming that displayed all important GPS data in the correct coordinate frame. This was able to provide us with an accurate prediction of direction adjustments to reach the desired location.

Software Team

Ground Control Station

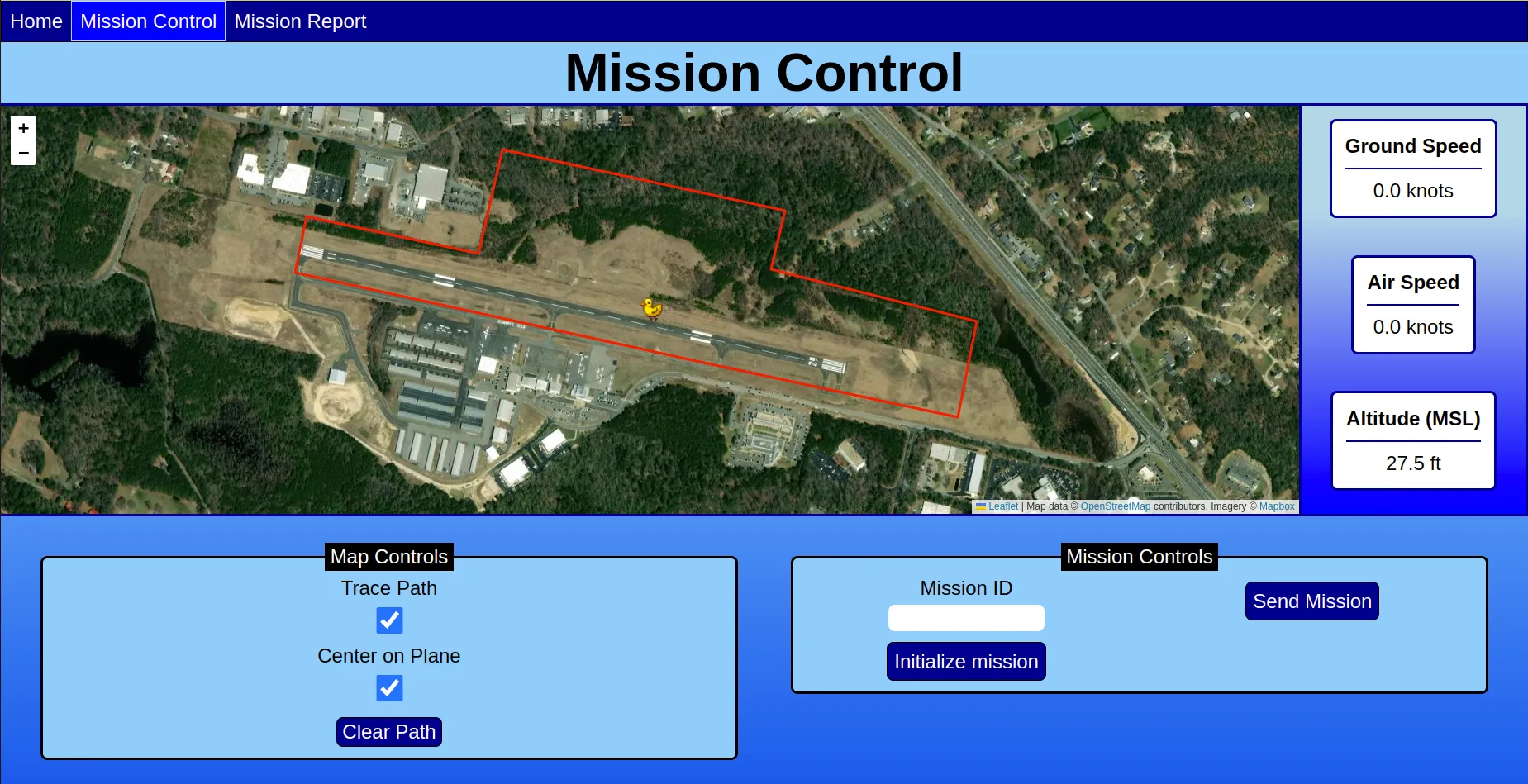

This year, we focused on connecting our Ground Control Station to our other components. We added capabilities to communicate with our new Path Planning and Computer Vision servers. We also set up the GCS to be able to send generated paths from the Path Planning server up to the plane.

In order to interface with all of the backend’s functionality, we continued work on our frontend, dubbed Houston. Originally, Houston was a react app that served to let us manage and control all assets of the mission. However, due to the inefficient code and technical debt that had been built up, we decided to rewrite the entire application using vanilla JavaScript, CSS, and HTML and call it Houston 2. Houston 2 ended up being the frontend that we used at competition, and it allowed us to generate, view, and send mission paths. In the future, it will also allow us to interface with our computer vision pipeline, once that is integrated with the rest of our system.

Computer Vision

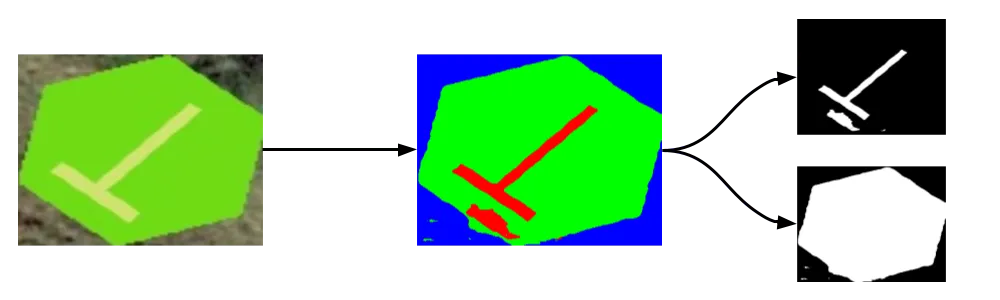

The team continued to make improvements to the components of our computer vision pipeline. To make our segmentation process more robust to handle many variations with targets on the ground we chose to reimplement it using a deep learning model. We chose to adopt the UNet model architecture, which found success in medical imaging. In addition, the team made improvements to our shape, character, and orientation classification models using a training technique called transfer learning. We also implemented an algorithm for the competition’s localization task which requires us to report the geolocation of computer vision targets. The algorithm works by converting the image coordinates of the targets to coordinates in the 3d world using camera model geometry.

In preparation for competition, the team worked to complete our new Computer Vision Server. The goal of the computer vision server is to have a simple, modular way to combine all the components of our computer vision pipeline while providing a simple way to interface with the GCS. This year, we integrated all our components (saliency, segmentation, localization, and classification) into the Computer Vision Server.

Path Planning

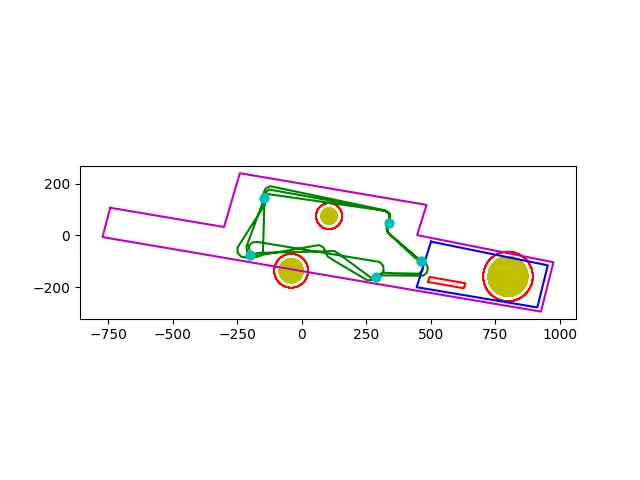

One of the larger undertakings of this year was the rewrite of our Path Planning system in the form of a Path Planning server. We chose to organize it as a web server to abstract away the underlying path planning algorithms from the GCS. Alongside the restructuring changes, we also chose to implement the Rapidly-exploring Random Tree (RRT*) algorithm because it provides many benefits for us going forward. This year, we fully implemented the algorithm for waypoint paths and successfully generated a mission path at competition that went through zero obstacles and never left the boundaries, forging the way for our 5th place finish!

Reflections

This year we outfitted and tuned Duckasaurus, developed code for aircraft design optimization, worked on the antenna tracker, power and system boards, improved the computer vision suite, and developed a target generator and path visualization tool. Triton UAS serves as an excellent opportunity for students to apply classroom knowledge to a hands-on, interdisciplinary project that prepares members well for a job in industry or academia after graduation. Despite the setbacks of the ongoing covid pandemic and the unfortunate crash of our plane (Swallow), our team has proved to be resilient and adaptable to the rapidly changing situations and achieved a top five finish in the competition. We will continue to improve our system and aim for another top five finish in the competition next year.