Due to the ongoing Covid-19 pandemic and the precautionary measures set by UC San Diego in response to Covid, Triton UAS switched all project work to a primarily online platform. In the virtual setting, we made significant progress on the design and analysis of our Unmanned Ground Vehicle (UGV) and new flight platform, Carbon Copy. Towards the end of the year, with lighter Covid restrictions and participating members receiving vaccinations, we held in-person work along with virtual work. In these meetings, we outfitted both the Swallow and the Ranger, a new autonomous flight platform, for two separate test flights.

On the community involvement side, Triton UAS held successful outreach events with Olympian High School’s engineering class and Otay Ranch High’s digital electronics and systems engineering classes. Our presentations gave an overview of airframe, embedded, and software subteams’ projects with the purpose of sparking interest in engineering as well as highlighting the importance of applying classroom knowledge to real-life problems.

Although the AUVSI SUAS Competition for 2021 had been canceled, we were still able to submit our Technical Design Paper for judging by the competition deadline. In addition, we took this opportunity to focus on our active design projects and to reflect and improve upon our engineering practices as a whole. Our current goal is to be well prepared for in-person manufacturing and intensified testing when restrictions are lifted.

Airframe Team

Design Optimization Program

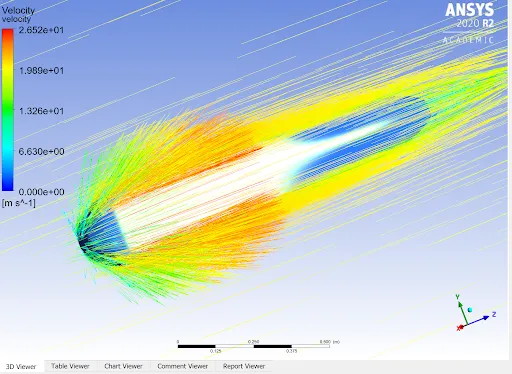

Over the course of the year, we continued the development and improvement of our gradient-based aircraft design optimization codes including our MATLAB code and new Python code, ADOPT, to be applied to our new plane, Carbon Copy. We implemented additional modules that will optimize the tail boom length, horizontal and vertical stabilizer sizing, and airfoils. With consideration from our program and a manually iterated fuselage, we were able to design and fully CAD our first benchmark aircraft for the Carbon Copy in Solidworks. We improved our low-fidelity aerodynamic models by tuning them to better match our high-fidelity ANSYS Fluent results, which we treat as true data due to the inability to carry out physical experiments.

In addition to design, we wrote a series of functions in MATLAB to perform composite analysis according to Classical Laminate Plate Theory. By doing so, we are able to analyze the structural behavior of a layup under given loading. This allows us to perform optimization to decide the orientation of each ply and determine whether more plies are needed. Our goal is to have this fully implemented into our overall design optimization program.

Analysis

With our first benchmark design created, we ran our first full aircraft performance evaluation using ANSYS, which simulates flow conditions throughout the domain. We used ANSYS to improve the accuracy of our design optimization code as mentioned before and iterate on our fuselage design. In the future, we plan on continuing to use ANSYS whenever a high-fidelity model is desired.

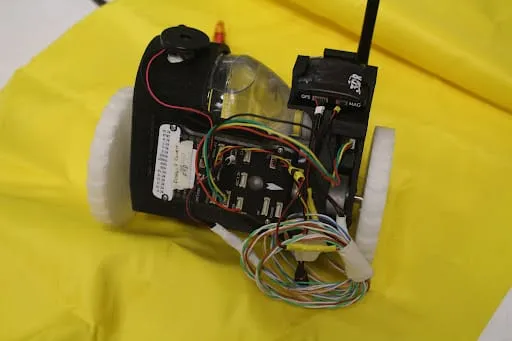

Unmanned Ground Vehicle

Throughout the course of the year, we made a considerable amount of progress with our UGV. We designed and prototyped our release mechanism to be implemented within the fuselage. The drop mechanism utilizes a latch attached to the UGV, which, when pulled, will drop our UGV from the plane. The doors were designed and modeled in Solidworks. The doors use a spring mechanism that allows the weight of the UGV to push its way out after the release mechanism initiates, and then the doors will close on their own using the tension from the springs. Our goal is to have a full prototype combining both the drop and door mechanism into the fuselage that will be ready for performance testing.

In addition to designing the release and door mechanisms, we designed simulation models and controllers to give the UGV autonomous driving and targeted landing capabilities. Moving forward, we intend to continue working with the embedded team to improve the drop and control mechanisms for increased UGV drop accuracy and driving performance using real-life testing.

Outfitting Ranger

The Ranger is our new trainer plane, which is used for training new pilots to fly in semi-autonomous flight modes and new members on tuning PID controllers. In spring quarter, we outfitted the Ranger with hinges, servos, mounts for electronics, a tailwheel, and a tailwheel attachment. The tailwheel attachment is a custom-designed and 3D-printed component that allows the tailwheel to move with the rudder giving the pilot steering control during takeoff and landing.

Embedded Team

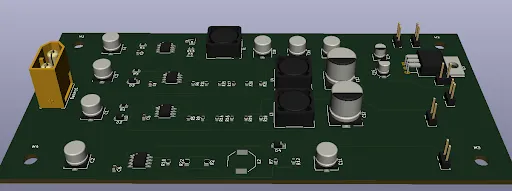

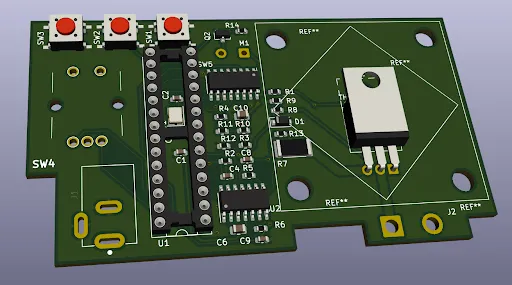

Power Board

The embedded team has completed the simulation of a new power board that includes step-up (boost) converters, step-down (buck) converters, and a linear regulator that will power peripheral devices such as the Rocket AC, servo motors, NVDIA Jetson, and two cameras. A schematic and printed circuit board (PCB) have been developed and the board is ready for manufacturing. We completed a bill of materials (BOM) that lists all of the selected electronic components for prototyping the board; we aim to have a working prototype by the end of the next quarter to use in test flights. Once the manufacturing of the board is complete, thorough hardware testing will take place.

Signals Board

In the past year, we have focused on a specific use case of the signals board: measuring and relaying temperature data to ensure the safe operation of in-flight components. Towards this goal, we first decided on a data flow model from the temperature sensor in the plane to the Ground Control Station, where a manual check can be performed. Moreover, a testing prototype of the corresponding signals board segment and an initial Mavlink code base to communicate the temperature data have been established. By the end of next quarter, the testing prototype will be revised to more accurately read in temperature data and integrated into the overall system to perform more extensive testing. We also plan to extend the capabilities of the signals board to handle multiple sensor readings, such as a coulomb counter to check battery levels in-mission.

Antenna Tracker

We also successfully developed a virtual prototype for the antenna tracker. To avoid spending a considerable amount of time on the script for parsing MAVLink messages, we opted to use Python to implement both the MAVLink parser and the mathematical models to obtain the pointing direction for the antenna tracker, as the MAVLink Python libraries seemed simpler for our use case. Currently, we have to test the connection between these Python scripts and the Arduino script that will command the servos to move to a given angle. Additionally, we are working on adding a GPS module to the antenna tracker. This module will automatically acquire the position of the ground control station for the Python scripts to use in the process of calculating the pointing direction.

Electronic Load

An electronic load has been designed to test the functionality of the new power board consisting of several DC-DC converters and to test the existing batteries. Computer-aided design (CAD) models must be created for mounting a heatsink and fan to the load PCB due to the high temperatures brought about by stressing the components. Manufacturing services are being sourced for viable pricing; we aim to build and test by the end of the year.

Software Team

Ground Control Station

We completely redesigned our Ground Control Station (GCS). Our goal with this project was to make the code easier to work with. Additionally, we strove to make the new GCS more modular, so that it could be easily integrated with our other projects (like the Computer Vision Server). In order to achieve this, we continued to use Google’s Go programming language because it provides great tools for networking and concurrent programming. However, we stuck with using Go’s standard library since it is simple to learn and well documented.

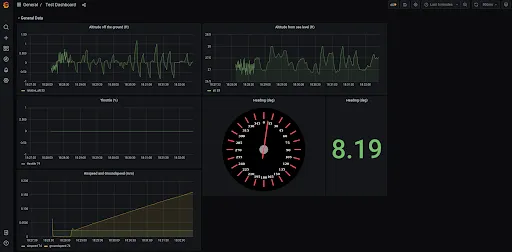

In addition to redesigning the backend, we set out to improve the way we processed flight data from our aircraft. We created a system where our backend server gathers telemetry data from the plane, processes the data, and stores it in a database called InfluxDB. In order to visualize this data, we used Grafana to take the flight data stored in our Influx database and display the data in a user-friendly, customizable fashion that allows us to see many flight measurements on a singular dashboard. This was a great improvement over our previous system, loggo, because it was difficult to use and lacked the ability to view multiple flight measurements at a time.

After completing the majority of the GCS backend, we began to work on the frontend, dubbed Houston. This will be a fully-fledged ReactJS web application that will allow us to track and manage all components of the mission as they are happening. So far, the framework of the website has been completed with only some of the functionality. Our goal for the next school year is to completely finish and polish this website so that it is ready for the competition.

Computer Vision

As a part of our initiative to redesign how our various components interface with each other, we set out to create a computer vision server (CVS) to manage our entire computer vision pipeline from a single location. Doing so organizes our computer vision tasks in a more modular way that abstracts away the underlying complexities. As a result, the CVS allows us to easily interface with our redesigned GCS without needing to deal with the inner workings of our computer vision pipeline.

Along with the Computer Vision Server, we continued to improve our existing computer vision algorithms, such as our color classification. Our goal going forward is to improve our localization algorithm so that we can identify the geolocation of targets in our pictures. Once this is finished, we should be able to insert all of our Computer Vision tasks into the Computer Vision Server and have a complete pipeline that can interface with the Ground Control Station.

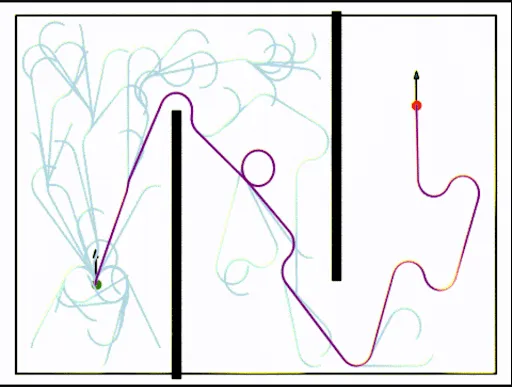

Path Planning

In the latter half of the school year, we began to rebuild our path planning code using the Rapidly-exploring Random Tree (RRT*) algorithm because it provides many benefits for us going forward. First, when implemented correctly, it will help prevent our path from going out of bounds and reduce redundancies in covering the search area. Second, RRT* will help facilitate dynamic obstacle avoidance as it can generate new paths mid-flight. So far, we have implemented the core RRT* algorithm, but we still need to integrate it with the format of the competition mission. Our goal for this next year is to fully integrate this algorithm so that it can be inserted into the pipeline with the rest of our subsystems.